Construction projects are built on tight schedules and even tighter budgets. However, one major disruptor that contractors and project managers often encounter is machinery downtime. Fortunately, much of this construction machinery downtime can be avoided through proper maintenance and attention to key mechanical systems, such as the radiator and heat exchanger of the machinery.

Each hour that a crucial piece of equipment remains out of service can result in substantial financial losses, project delays, and frustrated clients. That is why partnering with heat transfer specialists is an investment in smooth operations and fewer missed project deadlines.

Why Equipment Downtime Is a Major Threat in Construction

Machinery downtime poses a significant threat in the construction industry, where every hour of delay can have far-reaching consequences.

Financial Implications

For large projects, downtime can cost thousands or even millions of dollars per hour. When high-value machinery sits idle, labour costs, rental fees, and missed deadlines accumulate quickly.

Impact on Timelines & Labour Efficiency

When equipment unexpectedly breaks down, it creates a domino effect. Labour scheduling becomes inefficient, as workers wait for operational machines to continue their tasks. Project timelines stretch, sometimes resulting in breached contracts and late delivery penalties.

Breakdowns Are Often Avoidable

The majority of machinery failures are preventable with proactive maintenance. Neglecting system upkeep, especially in high-stress components like radiators and heat exchangers, is a leading cause of downtime.

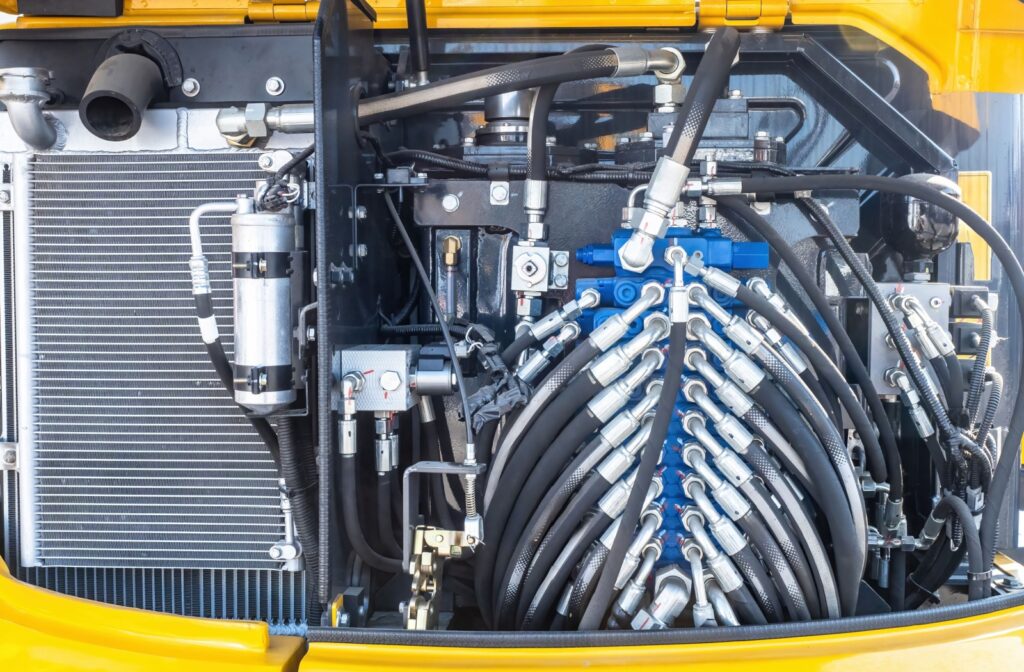

Common Causes of Construction Machinery Failure

Understanding what causes machinery breakdowns is the first step towards avoiding them. Cooling system failures are commonly at the heart of downtime.

Overheating from Clogged or Inefficient Radiators

Construction machinery operates under high temperatures, and cooling systems often bear the brunt of the strain. Radiators that become clogged with dirt, sediment, or road debris cannot regulate engine heat effectively, leading to rapid overheating during operation.

Leaking Coolant or Corroded Fittings

Even the most minor coolant leak can escalate into a full-scale machinery shutdown. Corroded fittings and damaged hoses can lead to coolant loss, which prevents the engine from maintaining an optimal operating temperature.

Heat Exchanger Blockages

Heat exchangers play a critical role in temperature regulation. These components can become blocked due to chemical deposits, dust, or debris, rendering them less effective at dissipating heat. This impedes performance and places unnecessary stress on the engine.

Seasonal Preparation Neglect

Construction equipment frequently experiences severe temperature fluctuations throughout the year. High-load conditions during summer and sub-zero operations in winter demand seasonal checks to make sure that radiators and cooling systems are ready to handle these stresses.

Without proactive servicing, cooling systems are prone to failure when exposed to extreme conditions.

The Role of Radiators & Heat Exchangers in Preventing Breakdowns

Radiators and heat exchangers are unsung heroes in maintaining uptime and ensuring equipment reliability. A properly functioning cooling system is crucial for maintaining your machine’s optimal performance and keeping your projects on schedule.

Regulating Engine Temperature Under Stress

Construction equipment engines operate for long hours and under heavy loads. Radiators and heat exchangers help prevent the engine from overheating, even under the most demanding conditions.

The Cost of Neglect

Failing to maintain these systems can result in more than just reduced performance; it also compromises the system’s integrity. Over time, engines subjected to overheating may suffer permanent damage, resulting in expensive repairs or even total replacement.

A Clean & Efficiency-Focused System Is Key

Keeping radiators and heat exchangers clean and well-maintained facilitates maximum efficiency, providing peace of mind that equipment will perform as needed when deadlines are on the line.

How to Maintain Your Cooling System for Maximum Efficiency

Preventive maintenance is the most effective strategy for helping your equipment operate smoothly and efficiently.

Regular Radiator Flushes

Over time, sediment and scale can build up inside radiators, restricting the flow of coolant. Performing regular radiator flushes removes these deposits, allowing your system to operate efficiently.

Pressure Testing

Leaks within the cooling system often go unnoticed until they lead to significant problems. Pressure testing is an excellent way to identify leaks in seals or fittings before they escalate into costly breakdowns.

Deep Cleaning & Repair

Plugged heat exchangers are common in construction machinery due to the often dusty operating environments. Routine deep cleaning and repair services help keep your heat exchangers functioning at peak capacity.

Rebuilds & Recoring

For equipment that operates under high loads or shows signs of aging, radiator rebuilds or recoring can restore the system to like-new performance standards. These services are invaluable for maximizing longevity and performance.

Usage-Based Maintenance Scheduling

Rather than relying solely on calendar-based servicing, schedule maintenance based on operating hours. This proactive approach accounts for the actual workload your machinery encounters, and getting the cooling system serviced on time.

Why Choose Northland Radiator for Your Equipment Maintenance

When considering partners for your equipment’s cooling system needs, Northland Radiator stands out as a trusted name in Alberta and beyond.

Decades of Experience

With over 45 years of experience serving our community, Northland Radiator has built a reputation for providing quality maintenance solutions to the construction and oilfield sectors. We understand the critical importance of uptime for your success.

Fast Turnaround

Downtime is costly, and our efficient service helps get your machinery back on-site quickly. From minor troubleshooting to complex repairs, our turnaround times prioritize your project’s timelines.

Custom & On-Site Solutions

Whether you need in-shop repairs or a custom-built radiator, we provide tailored solutions that meet your equipment’s unique requirements.

Take Action Before Downtime Costs You

Do not wait until machinery failure disrupts your project. Proactively servicing your cooling systems not only minimizes downtime but also protects your bottom line. Contact Northland Radiator today to schedule a maintenance assessment and make sure that your construction equipment is always ready for the job.